Visible Tread Splices

While visible and open tread splices are conditions rarely seen on street tires, they appear more frequently on racing tires, including the DOT-legal competition tires often used for road racing, track days and autocrossing. A visible tread splice is cosmetic in nature when it first appears; however, unless appropriate steps are taken, a visible tread splice will probably increase in severity until it becomes an open tread splice, requiring the tire be removed from service. Fortunately, the corrective actions may be as simple as rotating the tire and wheel to another position on the car, or remounting the tire inside out on its wheel for continued use in its current position.

Tires are assembled from dozens of components that are either extruded (a process similar to squeezing toothpaste from its tube) or calendared (the process of pressing warm uncured rubber onto steel, glass or fabric cords while they are passed between two rollers to produce a uniform flat sheet of reinforced rubber). A tire's tread is extruded by forcing warm, uncured rubber through a die to produce a continuous sheet of rubber that is the correct width, thickness and shape for the tire being manufactured. The continuous sheet of tread rubber is cooled and cut into individual tread slabs that are the correct length for the tire.

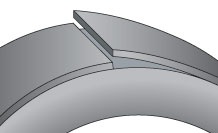

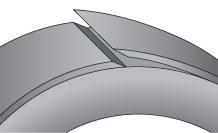

Since the tread slab is essentially a homogeneous blend of rubber, its most vulnerable area is where the two ends are joined together at the tread splice. The tread splice can employ either a butt splice (where the ends are cut at 90-degree angles), or a beveled splice (where the ends are cut on an angle). Most manufacturers choose to use the beveled splice for the assembly of their tires.

On street tires, the beveled tread splice will typically remain invisible (closed) throughout the life of the tire unless it was contaminated before the tire was cured. On racing and DOT-legal competition tires, the reasons a tread splice may appear are different.

In addition to being subjected to more acceleration, cornering and braking forces than their road-going counterparts, competition tire tread compounds are made of very pliable rubber that operates at higher temperatures as they conform to the track's surface and maximize traction. All of these conditions make competition tires more susceptible to tread compound wear and tear (the operative word to remember here is "tear").

Many drivers have experienced that their car's power is able to spin the tires as the vehicle exits the pits and/or unloads the inside drive tire as the vehicle accelerates out of corners. Tire spinning tears at the tread splices and is the most common cause of splices becoming visible or opening. The next greatest possibility of damaging a tread splice is when the stopping power of the brakes briefly slides the tires when slowing from high speeds or the driver locks the brakes and causes the tread splice to slide along the track. With today's manufacturing techniques, the final but least likely possibility is that the tread splice was contaminated during assembly before the tire was cured.

In order to minimize the risk of tread splices becoming visible, specific mounting instructions are used for many racing tires so the direction a tire rotates helps reduce the forces on the tread splice rather than increase them. The objective is to assure that the tire rolls across its tread splice when exposed to its most severe challenges of acceleration and braking. Since the tearing forces on a skidding tire are the opposite of a spinning tire, the tires on a non-driven axle are often mounted to reduce the possibility of tearing the splices if the brakes lock up causing the tires to slide.

Many race tire manufacturers provide guidelines on how to mount their race tires on wheels so they are suited for specific wheel positions. For example, the tire identifier (often a specification number, identification code or serial number that is branded on only one sidewall) may need to be mounted so that it faces one side on the driven axle and the opposite side on non-driven axles. With this type of marking, if a rear-wheel drive car should have the rear axle tires mounted with their identifier facing the right side of the car, the tires installed on the front axle should have their identifiers facing the opposite side. Conversely, if the same tires were mounted on a front-wheel drive car, the tires on the front axle would be mounted the same as the rear axle for the rear-drive car and the tires installed on the non-driven rear axle with their identifiers facing the left side of the car.

Use the following guidelines for mounting your tires on their wheels and installing them on the car if a visible tread splice has been experienced previously, or there is a concern that the car's ability to spin the tires and/or lock the brakes on abrasive, high-grip surfaces may put the tires at risk. See the chart below for selected brands and tire lines.

|

Sidewall With Full DOT Tire Identification Number Faces |

| Tire Brand |

Tire Line |

Tread Design |

Driven Axle |

Non-Driven Axle |

| Hoosier |

A7/R7* |

Symmetric |

Left |

Right |

| Toyo |

Proxes R888 |

Directional |

Branded Side Specific |

Branded Side Specific |

|

Proxes RA1 |

Directional |

Branded Side Specific |

Branded Side Specific |

|

Proxes RR |

Symmetric |

Right |

Left |

| Yokohama |

ADVAN A055 |

Symmetric |

No Recommendation |

No Recommendation |

Between Session Tire Inspections

Tire inspections between sessions should be used to confirm if any of the tire's tread compound splices have become visible. If a visible tread splice is detected during tire inspections, the tire should be repositioned in such a way to use the vehicle's wheel spin while accelerating or resistance during braking to close the splice rather than continuing to open it. While this may cause the tread splice to become visible on the other tire used on the same axle, the inspections and rotations should be repeated until the tire has worn out.

Continued use of a tire with a visible tread splice in the same wheel position will cause the tread compound to tear downstream from the splice, forcing the tire to be removed from service. The tires on very high horsepower cars should be rotated side-to-side between every session as preventative maintenance.

If all four tires on rear-wheel drive or front-wheel drive vehicles are the same size, they can be rotated to different wheel positions on the car to help equalize tire wear by using a crisscross or "X" rotation pattern. When using this pattern, the right front tire is exchanged with the left rear tire and the left front tire is swapped with the right rear. This helps balance tire workload from front-to-rear and side-to-side while continuing to protect the splices. When tires are mounted using this procedure, they should not be rotated directly from the front to the rear axle on the same side of the car.

In the case of an all-wheel drive car, the tires on both the front and rear axle would be mounted with their identifier facing the right side of the car because the risk of opening the splices by spinning tires far outweighs the risk of hurting them by locking the brakes.

If all four tires on all-wheel drive cars are the same size (width, as well as diameter), they can be rotated to help equalize wear by moving them straight front-to-back on the same side of the car. In this pattern, the right front tire is switched with the right rear tire and the left front tire is swapped with the left rear. While this will provide an opportunity to help balance the tire workload from front-to-rear while continuing to protect the splices, it cannot help balance side-to-side wear.

Rear-wheel drive cars that use larger tires on their rear axles than on the front would follow the same mounting orientation as described above for rear-wheel drive vehicles. However because of the staggered sizing used, the tires become position-specific without any easy way to rotate them to even out the workload. Because of the staggered sizes, the only possible tire rotation would be across the axle, and then only by remounting the tires on their wheels to prepare them for their new positions. While this would help balance the tire workload from side-to-side, it cannot help balance front-to-rear wear and is costly.

If a tire with a visible tread splice continues to be driven on until there is a gap between the leading and trailing edges of the tread slab, the tire should be immediately removed from service and replaced. Thoroughly inspecting all tires between every session or run group will help drivers discover and deal with conditions like visible tread splices, cuts and punctures before they become problems.

Was this post helpful?

421 of 760 people found this post helpful