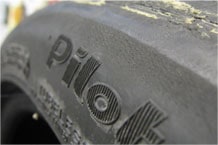

Tires used on the track have to work in a very tough environment: hard cornering, heavy braking, powerful acceleration, rubber grinding away against abrasive pavement lap after lap. To help you get the most from your tires, you should closely inspect them between every session as part of your regular track routine.

Tire Anatomy 101

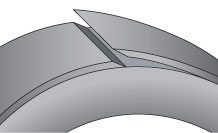

If you could peel back the rubber, you would discover that tires are complex laminate structures with many different types of rubber, fabric and steel forming a strong and stable, yet flexible, structure.

It helps to know what is on the inside when inspecting tires from the outside.

Monitor Tire Wear

It's easy to miss the slow change in remaining tread rubber as tires wear over time. Gone unnoticed, you may suddenly discover a tire has worn through the tread rubber and cannot continue to be used, prematurely ending your track day fun.

Street cars used on the track don't have suspensions optimized for even tire wear across the whole tread area. The result is usually a band of heavy wear on the outboard shoulder, especially on the front tires.

Use visual change in the remaining tread pattern as your guide to judge tire wear.

Once the lateral grooves in the shoulder start to disappear, the end is near - it's time to replace your tires.

Look for Uneven Wear

The perfect car/tire set up optimizes performance by utilizing the full tread area, and will wear tires evenly across. Unfortunately it's rare for a car to be perfect on the track, so odds are one part of your tire has worn a lot more than the rest.

The outboard shoulder usually does most of the work and shows the greatest wear.

The outboard edge of intermediate ribs can also wear rapidly, especially when the tread is deepest.

Reduce slip angle, especially before tires are up to full operating temperature, increase negative camber and increase air pressure to help to spread the workload across more of the tread area and therefore spread out the tire wear.

Check for Sidewall Roll-Over

If you see any scuffing or wear past the edge of the tread pattern, your tires are rolling over too far. The sidewall rubber compound is different than the tread rubber and is not designed to be driven on. Continued driving like this will quickly wear through the junction where tread and sidewall rubber meet, causing chunking and tearing of the tread rubber and will quickly destroy the tire.

If your tires are rolling over past the tread pattern, increase negative camber, increase inflation pressure and reduce slip angle while driving to keep the work concentrated in the tread area.

Check Your Hot Tire Pressures

As soon as you come off the track check your hot tire pressures and record them into your logbook (you do keep a record of all track activity, right?). By comparing your cold and hot pressures for every session you can dial in your set-up and also look for any trend in performance changes or slow air loss, etc.

Inspect Your Tires

Inspect your tires for cuts, tears, or other damage. Remove as much of the rubber pick-up as possible.

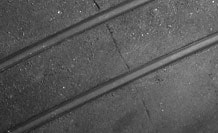

Visible or Torn Tread Splice

During the manufacturing phase, before the tire goes into the mold to cure and get its final shape, a wide sheet of uncured tread rubber is wrapped around the tire casing above the steel belts. There is a beveled junction where the ends of that sheet meet, which becomes invisible as the tire cures in the mold.

Sometimes, braking force or torque and/or wheelspin from acceleration can put enough stress on this junction to cause it to become visible as a faint line that runs across part or all of the tread area. Proper tire rotation will prevent it from getting deeper, but if left in the same wheel position it will likely grow further, eventually tearing open to the point the tire must be replaced. Usually, after rotating away from the wheel position where the splice first became visible, the splice will eventually disappear as the tire continues to wear from use.

Visible Tread Splice

If the splice is at the visible stage, the tire should be rotated to help hold the beveled splice closed. Rotate front to back on the same side of the vehicle, or side-to-side across the same axle to help hold the splice closed rather than continue to pull it open.

Torn Tread Splice

If the splice is torn open far enough to see the flat under tread rubber that lies beneath the tread compound, then the tire should be removed from service.

Don't forget to look over the rest of the car, too.

- Check fluid levels - brake fluid, coolant, oil

- Check brakes - do you have enough pad thickness to continue, are the rotors OK?

- Check wheels - look for cracks or gouges

Fill out your logbook after every session. Just a few quick notes every time you drive on the track will give you a wealth of post-event knowledge that will help you go faster, run longer and have more fun.

Was this post helpful?

382 of 717 people found this post helpful