The contact patch of a tire that’s inflated with pressurized air is also called its tread footprint. The contact patch is the result of the vehicle’s weight pressing its round tires against the road, requiring their treads to conform to relatively flat surfaces. A tire’s sidewalls and treads are engineered to deflect (bend, stretch and flatten slightly) to form traction-producing contact patches.

Since tires continuously roll whenever the vehicles are driven, each tire’s contact patch only exists temporarily when its tread conforms to the road. Sidewalls and treads return to their unloaded, round shape when the vehicle weight is removed from that portion of the tread as the tire continues to roll.

A tire contact patch’s final dimensions depend on the tire size and inflation pressure being used, as well as how much load is being carried. A compact car tire’s contact patch size is about 25 square inches, a bit bigger than the size of a 4” x 6” printed picture.

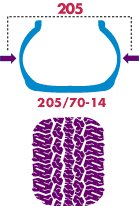

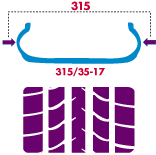

The shape of a tire’s contact patch is also dependent on the tire’s profile (aspect ratio). Most passenger car and light truck tires feature higher profile tire sizes that typically have longer and narrower contact patches; while most touring and performance tires feature lower profile sizes that have shorter and wider contact patches.

A driver's ability to control their vehicle depends on the traction developed between their tires and the road. It's the tire’s contact patches that provide that connection.