Our quality standard for wheels is very high and the manufacturers that we represent in this market understand that we constantly monitor products to ensure that quality products are sold to our customers. But what determines quality?

Manufacturing Process

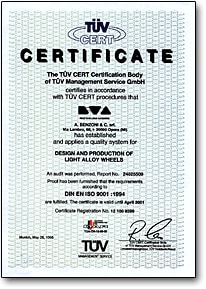

Manufacturing processes and levels of testing are critical to a wheel's structural integrity. (Read more in "Wheel Construction.") International quality standards such as ISO9001, QS9000, TUV of Germany or VIA of Japan, establish important production and quality standards that manufacturers must follow. In addition, dimensional tolerances based on strict, Original Equipment market standards versus the more "casual" standards allowed for many aftermarket products should be met. Even durability standards for finish are different between the Original Equipment market and the aftermarket.

Proper Fit

An accurate fitment is the difference between good, better and best. Critical wheel dimensions such as width, diameter, offset, center bore, brake clearance, as well as load factor and lug hardware are the basics when it comes to properly fitting aftermarket wheels. Installation also requires a high level of sophistication. Many new vehicles are available with features such as ABS, traction control and other features that create a more difficult environment for installing aftermarket wheels. Stability control systems, run-flat tires, large high performance brake systems and staggered wheel and tire sizes are also factors to be considered when establishing accurate fitments. Wheel manufacturers with product design, research and development teams work to determine proper fitment as part of the manufacturing process.

Protective Finish

The type and quality of protective finish on your wheel (as well as proper maintenance) will determine how your wheels look years from now. Check for finish warranties backed by manufacturers with outstanding reputations for quality.

Reputation and Heritage

The reputation of a manufacturer is a strong indicator of quality since it is quality upon which a distinguished reputation is built. It takes time to build a positive reputation and a commitment to maintain it is important. And know a wheel company's roots. Many wheel manufacturers first established themselves in the motorsports arena and apply that technological and philosophical foundation to their production of wheels for use on the street.

Our Commitment to Quality

We constantly review wheel data from new vehicles to be sure that we are aware of the Original Equipment sizes and packages offered. We physically inspect many of today's new vehicles and often supply technical data to some of the manufacturers outside the U.S. that may not have access to certain vehicles in our market. For many wheels that we import or represent, we specify certain dimensions that we require to ensure wheel fit and maintain our high quality standards.

Was this post helpful?

433 of 858 people found this post helpful